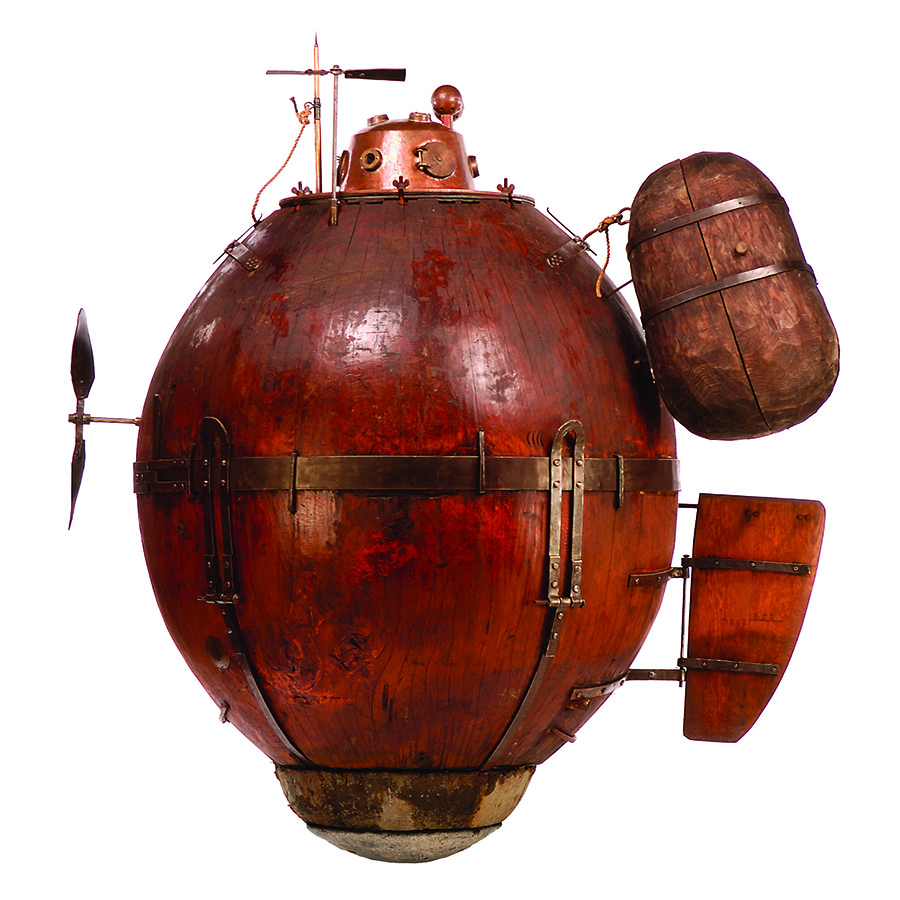

Carving the Bushnell Turtle Submarine /

In 1776, during the American Revolution, a Connecticut Yankee by the name of David Bushnell had a daring idea to break the British blockade of New York harbor: he would build a one-man submarine and somehow attach a bomb to the underside of the British ships and blow them up. Intrigued, Rick and Laura Brown of Handshouse Studio led the effort to re-create the building of a replica of this wooden submarine, nicknamed the "Turtle," using only the tools and technologies of the day. With help from students and professional craftsmen plus the submarine expertise of the United States Naval Academy, they built and tested and ultimately proved the seemingly radical idea of Bushnell's.

January 2003: Replicating of the Bushnell Turtle

Handshouse Studio directed and coordinated the making of the replica of Bushnell’s Turtle in collaboration with Massachusetts College of Art and the United States Naval Academy.

Rick Brown and Laura Brown, directors of Handshouse Studio and faculty members at the Massachusetts College of Art, led the making of the replica of the Bushnell Turtle through research, design and project development. The research included locating and analyzing original letters and written histories of the American Revolution period and investigating period technologies and materials that would have been used in the construction of the original Bushnell Turtle.

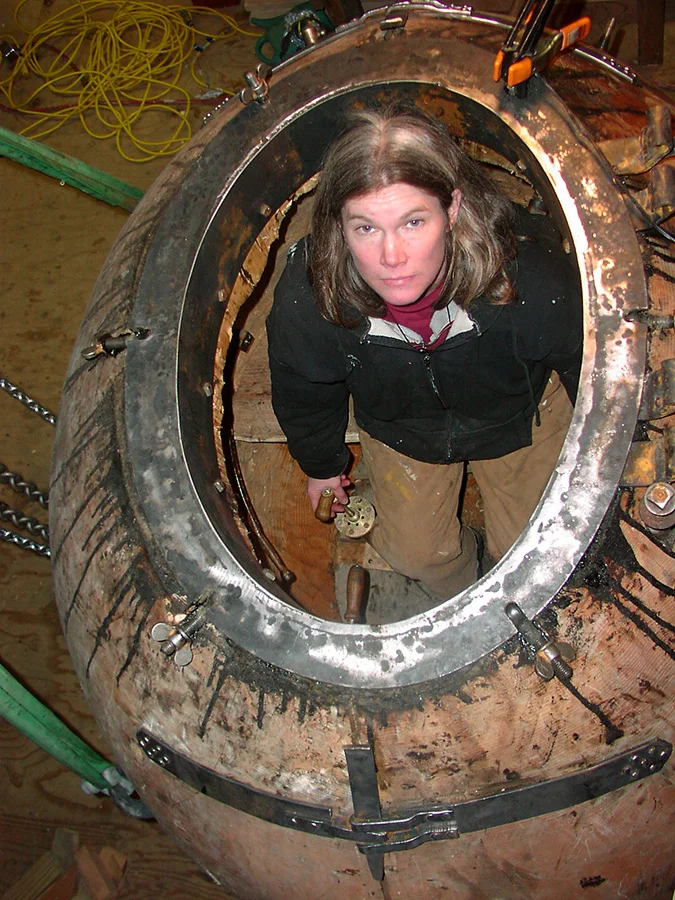

With this information, they attempted to remake the Turtle using similar materials, technologies and processes. Handshouse Studio collaborated with faculty, students and alumni at Mass College of Art and professional craftsmen from the Timber Framers Guild to create the Turtle. Period processes used included copper raising, bronze casting, brass braising, blacksmithing, glass blowing and felting. The wooden body of the Turtle is made from a single log—a process used widely by the Pequot Native Americans at the time—whereby the large log was split with wedges and hewn with period hand tools.

The fine skills and dedicated work contributed by Mass Art affiliates and members of the Timber Framers Guild during the intensive ten-day workshop at Handshouse Studio made the Turtle beautiful, historical and operable. It was successfully water tested at Snug Harbor in Duxbury, Mass. on January 9 and 10, 2003. It proved to be watertight and all the moving parts functioned properly.

Testing the Replication

From March 24 to 28, 2003, the Turtle was thoroughly tested at the United State Navel Academy in Annapolis, Maryland, in their Hydromechanic Laboratory tow tank. Unmanned tests were made to assure water-tightness. Drag tests verified calculations made by Midshipmen in their Naval Architecture and Ocean Engineering department proving, once again, the Replica to be seaworthy.

Professor Lew Nuchols of the Naval Academy operated the Turtle in manned tests diving to a depth of 15 feet and reenacted the attack of the Turtle on the HMS Eagle by screwing the auger screw into a mock up ship hull rigged in the tank. The Turtle replica performed similarly as the original described by Ezra Lee and David Bushnell in 1776 and the mock bomb successfully attached and deployed, albeit with difficulty. Finally, on April 6, 2003, the Turtle returned to open waters at Duxbury, Mass. in an exercise to demonstrate a traditional launch method using draft horses and a cart. Once in the harbor, it was operated on the surface by Rick Brown to understand how it maneuvered in open waters using the forward propeller and rudder. Again, it was a successful event.

In 2004, the Discovery Channel, England’s Channel 4 and France’s Channel 5 aired a one-hour documentary film about the reconstruction of the Turtle and its historic undersea warfare mission during the American Revolution. The film, one in a series entitled “ Machines Lost in Time,” was programmed to be broadcast in the U. S., Great Britain, France and Canada. A National Geographic magazine article appeared on this same subject in the November 2003 issue.